Liquified Natural Gas(LNG) - An Altenative fuel for shipping

Liquified Natural Gas(LNG)

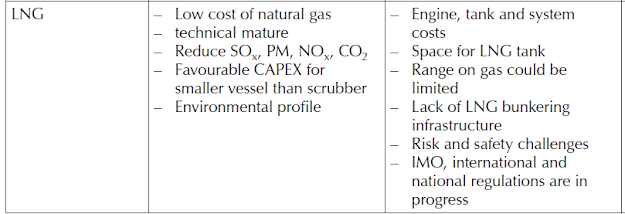

The shipping industry has to comply with a number of regulations pertaining to the prevention of pollution and the emission of potentially harmful substances to the environment. IMO is the international agency responsible for issuing and adopting regulations applicable to international shipping. The IMO member states are responsible for implementing the regulations.

General

The main component of liquefied natural

gas (LNG) is methane (CH4 ), the hydrocarbon fuel with the lowest carbon

content, and therefore with the highest potential to reduce CO2 emissions

(maximum reduction: roughly 26 percent compared to HFO). LNG has more or less

the same composition as natural gas used in households, for power generation

and by the industry. The production process of LNG ensures that it is

practically sulphur-free. Therefore using LNG as fuel does not produce any SOx emissions.

Since the boiling point of LNG is approximately –163°C at 1 bar of absolute pressure, LNG must be stored in insulated tanks. The energy density per mass (LHV in MJ/kg) is approximately 18 percent higher than that of HFO, but the volumetric density is only 43 percent of HFO (kg/m³). This results in roughly twice the volume compared to the same energy stored in the form of HFO. Factoring in the shape-related space requirements, cylindrical LNG tanks typically occupy three times the volume of an equivalent amount of energy stored in the form of fuel oil.

Technology

The technology available for the usage of LNG as fuel onboard are listed below-

• steam turbines

• lean-burn spark-ignited (LBSI) engines, usually four-stroke, medium-speed

• low-pressure injection dual-fuel

(LPDF) engines that are four-stroke, medium-speed

• LPDF engines that are two-stroke,

slow-speed

• high-pressure injection dual-fuel

(HPDF) engines that are two-stroke, slow-speed

(medium-speed is being introduced)

• gas turbines

The many years of experience with LNG carried as cargo on gas carriers where the boil off-gas is used as fuel, have also enabled the maritime industry to build competence and develop standards that have been used as guidelines for emerging use as LNG as a fuel for other vessel types.

LNG is becoming popular

for several reasons.

First, it contains very little sulfur. Additionally, LNG engines are tuned to either emit low nitrogen oxide (NOx)emissions—at the cost of higher methane emissions in some cases—or to incorporate NOx reduction technologies such as exhaust gas recirculation (EGR) or selective catalytic reduction (SCR). These low sulfur oxide (SOx) and NOx emissions make LNG an attractive fuel for ships that operate in Emission Control Areas (ECAs), where ships must comply with more stringent air quality standards.

Second, LNG is, and has been, less

expensive than MGO and is now in some regions cheaper than heavy fuel oil (HFO).

Third, The IMO’s Energy Efficiency Design Index (EEDI) regulations require new ships to become less carbon intensive over time. The EEDI regulates the amount of CO2 that can be emitted to move goods or people a given distance. Because the EEDI currently only regulates CO2, ship owners who buy LNG-fueled ships have an easier time meeting the standards. This is because LNG emits approximately 25% less CO2 than conventional marine fuels in providing the same amount of propulsion power.

Bunkering

Just like the bunkering of traditional oil fuels, LNG bunkering may be performed in different ways. At present, most LNG bunkerings are made either from truck to ship or from small intermediate bunker terminals. During the development of the different supply chains as described in appendix 2 the following bunkering solutions were considered: truck to ship (TT S), intermediate tank via pipeline to ship (IT PS), ship to ship (STS), and container to ship (CTS).

Infrastructure

Today, there are 60 supply locations worldwide, including Singapore, the Middle East, the Caribbean as well as Europe, according to the latest data in DNV GL’s LNGi business intelligence portal. A further 28 facilities have been decided and at least 36 are under discussion.Shown on map.

|

Source- DNV-GL |

Thanks for reading our article.

Comments

Post a Comment

Please give your valuable advice and do comment.